Shane ... Nope .. Windsor the town is, but Windsor Ply is all over the parts of BC I have been to - one in North Van, one off Lougheed Hwy in Vancouver, one in Duncan, bought nice wood at one time or another from them all. In fact, my first acoustic was built from a beeswing figured and quartered piece of what I thought was a heavy mahogany (hey, 1995 or so, what did I really know then) from the Duncan store - turned out to be eucalyptus - made a beauty guitar. A couple years later, same store, bought some unreal curl and burl soft maple - guy even let me take half the board, the end that I wanted !!!! Still have enough of that for another electric top.

|

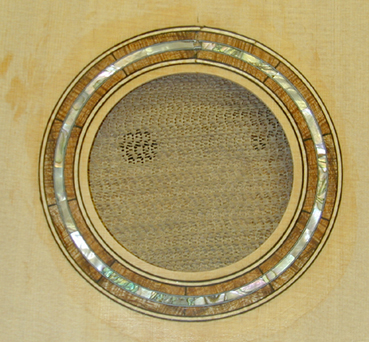

In the long run all the clients changed either to abalone or a divided pie ring MOP rosette.

In the long run all the clients changed either to abalone or a divided pie ring MOP rosette.  )

)